A SMOGLESS HEAT

FOR THE GENERATIONS

Equipment service life is approx. 50 years!

EFFICIENCY

unchanged over the entire lifetime

VERY SMOOTH

OPERATION

Ecology at its finest

It has been comprehensively tested – it meets the strictest environmental protection and energy savings requirements. Its operation is neutral for people, animals and plants. Does not emit flue gas, carbon dioxide, sulphur, or benzopyrenes. It is made of recyclable materials.

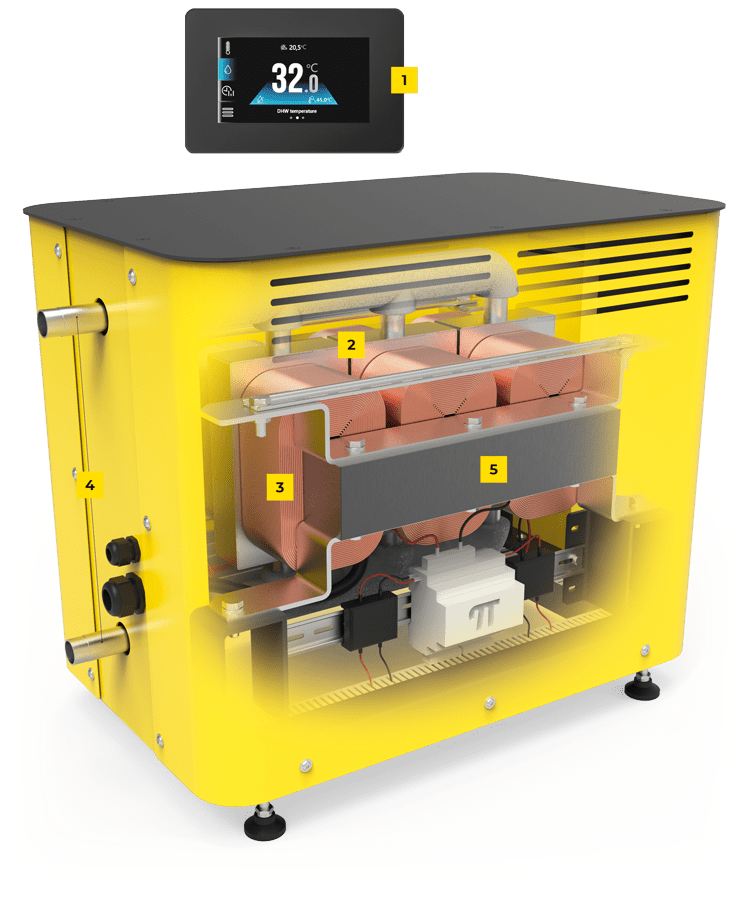

The controller allows adjusting the operation of the boiler to the energy tariffs, cooperation with the PV system and temperature sensors. It ensures simple and intuitive operation.

Heat exchanger is made of durable stainless steel, which does not interact with the other materials. It has a direct impact on the reduction of the costs related to the operation, high efficiency of the boiler and 20-year warranty.

π boiler quickly heats water to the optimum temperature – even to 80°C. Therefore, it can operate with various heating systems like floor warming systems and radiator heating systems.

Design and equipment of the boiler ensure the simple connection of the device to new and to the existing system e.g. instead of a gas-fired boiler or a boiler fired with solid fuels.

π boiler does not have any mobile components, which are subject to wear and tear. Therefore, the induction boiler can be provided with the longest warranty available on the market.

Contact us to obtain more information:

FOR HOME

AND COMPANY

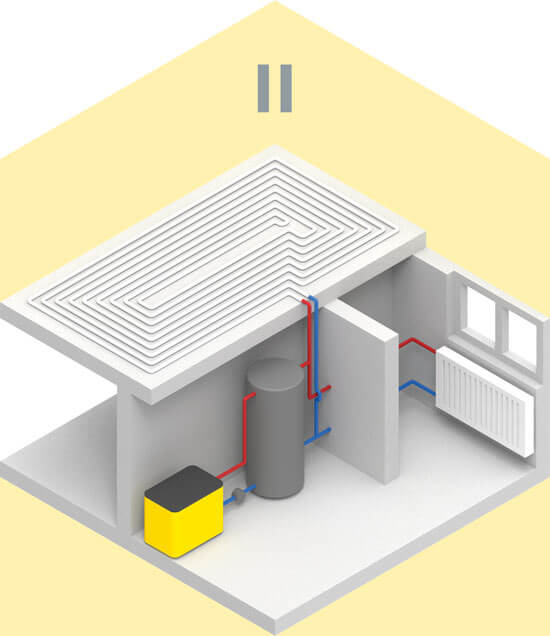

direct connection of the boiler to the system

The first operating mode allows connecting boiler directly to the supply and return of the existing or newly designed system. It is required to use a pump “on return”.

connection to the system via the central heating buffer tank

It is required to use a pump “on return” located between the boiler and tank and the buffer tank with appropriate capacity adapted to the needs.

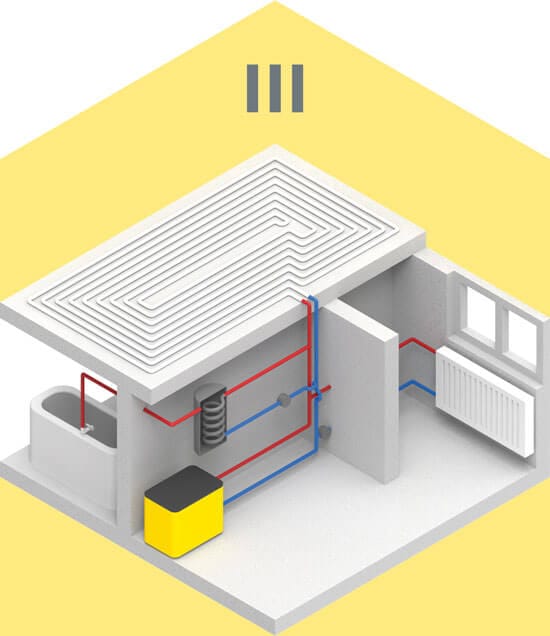

direct connection of the boiler to the central heating system and domestic hot water system via the tank with a coil pipe

It is required to use 2 pumps: “on return” from the central heating system and “on return” from the domestic hot water buffer.

connection to the system via the central heating and domestic hot water buffer tanks

It is required to use 2 pumps: “on return” from the central heating buffer tank and “on return” from the domestic hot water tank.

![water heating time by the induction boilers]](img/lazyload-ph.png)

Heat in a few minutes

π series induction boilers transfer thermal output almost immediately heating up the water in the system or buffer tank.

Calculator of water heating-up time

Filling the fields in the following forms and pressing “CALCULATE” button you may calculate the power and/or time required for heating specified volumes of water.

Time

Power

FOR ANY AREA

π boiler can heat both rooms for residential purposes and large volume buildings. Individual devices can be connected into cascades obtaining unlimited heating power.

Longer system lifetime

A phenomenon of anodic passivation of metals, which forms protective coatings on the surface of the walls of the system, occurs during the operation of the boiler. This process prevents the formation of limescale and corrosion of metal components of the central heating and domestic hot water systems.

Contact us to obtain more information:

FREE HEATING?

– IT'S POSSIBLE!

Owners of the photovoltaic power stations can use DSO electricity grids as an accumulator, storing the excess of electrical energy generated in the domestic PV system, when it is not consumed in the house and it allows using it during the evening or on days when the energy demand is higher.

The recommended size of a photovoltaic system

Heated area: 140 m²

Number of inhabitants: 2 adults, 2 children

| Building energy-efficiency rating | Size of the photovoltaic system [kWp] | Annual heating cost |

|---|---|---|

| A++ | 5,31 | 0$ |

| A+ | 5,83 | |

| A | 9,45 | |

| B | 16,16 | |

| C | 21,84 | |

| D | 28,66 |

| Building energy-efficiency rating | Size of the photovoltaic system [kWp] |

|---|---|

| A++ | 5,31 |

| A+ | 5,83 |

| A | 9,45 |

| B | 16,16 |

| C | 21,84 |

| D | 28,66 |

Annual heating cost: 0 $

Energy security

Electric utility companies apply power factor penalty charges – it applies to the prosumer type of agreements in particular. π induction boilers maintain these parameters on a safe level, without exposing the user to unexpected costs.

Heating costs calculator

For your convenience we made the application allowing preliminary estimation of heating costs and selection of suitable equipment available at: kalkulator.kociol-indukcyjny.pl

We invite you to tests!

Contact us to obtain more information:

TECHNICAL

DOCUMENTATION

| Parameter | Unit | Boiler model | |||

|---|---|---|---|---|---|

| 3,2 | 10 | 21 | |||

| Dimensions | L | [mm] | 520 | 587 | |

| S | [mm] | 356 | 405 | ||

| H | [mm] | 666 | 535 | ||

| Rated power | [kW] | 3,2 | 10 | 21 | |

| Approx. heating area | [m²] | ≤ 80 | ≤ 180 | ≤ 350 | |

| Frequency | [Hz] | 50 | |||

| Efficiency | [%] | 98,6 | |||

| Maximum power consumption | [A] | 16 | 28 | ||

| Rated current of overcurrent circuit breaker | [A] | 20 (C20) | 20 (C20) | 40(C40) | |

| Minimum cross-section of power cable | [mm] | 3 × 1,5 | 5 × 2,5 | 5 × 6 | |

| Max. permissible work pressure | [bar] | 3 | |||

| Outlet temp. adjustable | [°C] | ≤ 80 | |||

| Outlet temp. allowed | [°C] | 90 | |||

| Operating time | [h] | unlimited | |||

| Emitted noise | [dB] | ≤ 35 | ≤ 41 | ≤ 44 | |

| Junction box with fuses | — | Integrated | separate component for installation on the wall | ||

| Supply | [V] | 1 × 230 V | 3L ~400 V | ||

| Weight | [kg] | 85 | 128 | 178 | |

| Ingress protection | — | IP 21 | |||

| Boiler connectors | [inch] | 3/4 | |||

| Colour touch display with room thermostat | — | ✗ | ✔︎ | ✔︎ | |

| Bi-color display with potentiometer | — | ✔︎ | ✗ | ✗ | |

| Option to connect two additional thermostats | — | ✗ | ✔︎ | ✔︎ | |

| Option to read and analyze data from the sensors | Circulating pump | — | ✔︎ | ✔︎ | ✔︎ |

| DHW pump | — | ✔︎ | ✔︎ | ✔︎ | |

| Central heating pump | — | ✔︎ | ✔︎ | ✔︎ | |

| Mixing valves | — | ✔︎ | ✔︎ | ✔︎ | |

| Buffer pump | — | ✔︎ | ✔︎ (2 sensors) | ✔︎ (2 sensors) | |

| Online monitoring of boiler operation | Data history | — | ✔︎ (option) | ✔︎ | ✔︎ |

| Alarms | — | ✔︎ (option) | ✔︎ | ✔︎ | |

| Operation schedule | — | ✔︎ (option) | ✔︎ | ✔︎ | |

| Graphic visualization of the system operation | — | ✔︎ (option) | ✔︎ | ✔︎ | |

| Service assistance | — | ✔︎ (option) | ✔︎ | ✔︎ | |

| External sensor support | — | ✗ | ✔︎ | ✔︎ | |

| Automatic switching between summer and winter mode | — | ✗ | ✔︎ | ✔︎ | |

FAQ

π series induction boiler is a combination boiler supplied with alternating current (single or three-phase) intended for heating in both central heating and domestic hot water systems. Available boiler powers: 3.2kW; 10kW; 21kW. π series induction boiler is a device in a class of its own. It has many advantages. It is a good solution for single-family houses and residential developments, private companies or public utility buildings expecting reimbursement of expenses. The boiler is extremely efficient. It is also cheaper in operation in comparison to the modern devices available on the market.

π induction central heating boiler is electro-magnetic equipment. A three-phase dry-type transformer with shorted secondary winding is the basis of its design. Secondary winding becomes a heating chamber in this design. The whole thermal power generated in the heating chamber is transferred to flowing water. The design of chamber ensures that the thermal load of the heat exchanger will not exceed 3 W/cm² (for comparison: a thermal load of heaters in resistance boilers is 22 W/cm²). Water is subject to “electromagnetic treatment” during the heating process. Thermal energy is generated by the electromagnetic field directly in the heating chamber - heat exchanger, which is located on transformer columns between halves of the primary winding. Such a solution ensures a considerable reduction of losses of the electromagnetic field. The heat exchanger is made of high-quality, acid-resistant, food-grade steel. The boiler is manufactured using modern materials and achievements of the state-of-the-art technology what ensures that its service life may reach even 50 years! This is a unique solution.

π series induction boiler meets all the safety standards. Generated electromagnetic field used to heat the boiler water is completely safe for the surrounding area. The special design of the equipment makes that a flux of electromagnetic field is aimed directly on the heat exchanger made of stainless steel. Furthermore, a residual electromagnetic field is stopped inside the equipment due to dedicated screened housing. The electromagnetic field has no impact on the surrounding area and equipment located near the boiler.

It is advisable for the User to perform service inspections. First service inspection should be reported (through the system) after five (5) years of boiler operation. Successive inspections should be reported every two (2) years, counting from the date of the first service inspection. A calendar of performed service inspections is available in the system for each individual User after obtaining a Certificate of a 20-year warranty. The User will be informed about upcoming service inspection by automatic system notifications sent through the e-mail to an address given during registration. A condition for the arrival of the service is the generation of requests by the User in the system.

Of course - YES. However, it should be noticed that photovoltaic systems, and the fact that they generate electrical energy, are systems operating independently from the heating systems - induction boiler. The whole excess power from the electrical energy generated by the photovoltaic systems, during e.g. summer, can be “returned” to the electrical network and can be used for boiler heating during the heating season. It is not necessary to install additional equipment, modules or telemetry units. The boiler is simply supplied with electrical energy drawn from the grid and generated earlier in the domestic photovoltaic power station.

While designing the π series induction boiler we focused on its efficiency and cost-effectiveness for the Users:

Using excess power from the generated electrical power by own, domestic photovoltaic power station.

Who do not have a photovoltaic system in their households.

Installation of a sufficient number of photovoltaic systems is not a cheap and easy task. Not everyone has sufficient space on the roof of the residential building or plot, not everyone wants to or can bear the costs related to this operation. Therefore, we prepare a connection diagram for the boiler ensuring efficient and cost-effective operation, using so-called special tariffs, which can be purchased from the distribution system operator. Using such tariffs the savings related to heating using π series induction boiler may reach even:

25% – for heater system,

35% – for a mixed system,

45% – for floor warming system.

The amount of electric current used for heating of central heating and/or domestic hot water systems can be estimated only based on the energy efficiency index expressed in kW/m²/year. This index is a very specific parameter for each building informing about its heat demand. This index indicates also the energy efficiency of the given building.

The energy efficiency index is given in the building plans and specifications (newer buildings) or it can be obtained by ordering the “building energy audit” based on which the given audit company will prepare suitable calculations and will provide you with the all required parameters of the building. If you do not have the documents confirming the energy efficiency index, it can be estimated - we remain at your disposal in this respect.

The only condition to be met to install the induction boiler safely is to meet the following requirements for the cable connection:

| Required 3-phase electric service line | ||

|---|---|---|

| Induction boiler 10 kW | Induction boiler 21 kW | |

| Section of power cable | min. 5 × 2,5 | min. 5 × 6 |

| Protection | B25 (D20) | D40 (C50, B50) |

| Available capacity for the equipment | 10 kW for the equipment + power for household (usually, on average: 14-15 kW) | 21 kW for the equipment + power for household (usually, on average: 25-26 kW) |

Yes! π series induction boiler is high-temperature equipment. What does it mean? It means that water on the outlet from the boiler can have even 85°C. Depending on the needs we may set the sufficiently high temperature to the radiator heating system what is impossible e.g. in the case of heat pumps. Therefore, if you have a house with a heat reception in form of radiators – the induction boiler is the only and ideal solution.

π series induction boiler is a 2-function device what means that it can heat both central heating systems (supplying heat to the house) and the domestic heating water systems (supplying hot water in taps). We recommend using special enameled tanks with coil pipe, which are also offered by PEREKO, for heating of domestic heating water.

We recommend using special vertical tanks, enameled and with coil pipe (SIGMA CWU-1 or SIGMA CWU-2), which are also offered by PEREKO, for heating of domestic heating water (dhw). The selection (capacity) of the corresponding tank for dhw depends mainly on the number of residents using domestic hot water. To ensure continuous access to hot water we should average and assume the following calculation for the selection of the suitable capacity of the tank:

50 l (water) x 4 (number of members of a household) = 200 l

New meters installed in the prosumer’s buildings during investments in domestic photovoltaic micro-installations are not only an occasion to collect better information related to consumed and supplied electrical energy. They can be also used to add extra costs related to a so-called capacitive reactive energy... And this is already happening...

A very important aspect during the selection of the heating source is to follow the indication of how and whether the given equipment compensates the reactive power. Currently, there are is heating equipment (boilers, pumps or furnaces) on the market, which could deal with this problem. But are you sure? From the very beginning, during the designing of the induction boiler, we considered reactive power and we strongly focused our attention on this aspect. Shortly, equipment with a high tg φ factor generates and exports the undesirable reactive power to the grid. The higher the factor of the given heating device, the more reactive power is exported to the grid and the bigger financial penalties may be imposed on the prosumers. It is possible to use suitable “compensators” but it is connected with high costs, uncertainty, lack of safety, and fear that in the case of compensator failure the penalties may be imposed.

This problem does not apply to the users of the π boilers - why? The allowable value for tg φ in Poland is: tg φ <0.4. For π series induction boilers these values are as following: π 10 kW – tg φ = 0.07; π 21 kW – tg φ = 0.11.

You are safe!

Energy performance of a building of the building, that is its energy efficiency, is a preparation of the building to provide the comfort of its operation as intended while ensuring the lower possible energy consumption by this building. Assessment of the energy efficiency is an assessment of a set of building properties that have an impact on the consumption of energy by this building required for its operation, including among others assessment of the thermal performance of building partitions and efficiency of the systems and equipment installed in it. The following table describes briefly energy-efficiency ratings for residential buildings and the range of energy efficiency indexes.

| Energy class | Building type | UE index [kWh/m²/year] | Heating method | Source | |

|---|---|---|---|---|---|

| Utilities | Efficiency [%] | ||||

| A++ | Zero-energy | ≤ 10 | Electric current | 100 | Photovoltaics, wind energy, energy distributor |

| A+ | Passive | 10 – 15 | |||

| A | Low-energy | 15 – 45 | |||

| B | Energy-efficient | 45 – 80 | Electric current, natural gas | 98 – 100 | Photovoltaics, wind energy, energy distributor, natural gas distributor |

| C | Medium energy-efficient | 80 – 100 | |||

| D | Legal minimum (meeting the current legal requirements) | 100 – 150 | Electric current, natural gas, coal, wood | 68 – 100 | |

| E | Energy inefficient | 150 – 250 | Natural gas, coal, wood | 68 – 98 | |

| F | Highly energy-inefficient | ≥ 250 | Coal, wood | 68 | — |

π series induction boiler is a completely maintenance-free boiler. You only set the temperature setback on the controller, which should be maintained by the device on the buffer tank and hours when the boiler should be switched on to heat up the water inside the tank. While using the systems without the buffer tank, the boiler operation, and therefore the temperature in rooms, is controlled only by the room controller. Boiler activates automatically when the lowest rates for kWh in G12 or G12 tariff are applicable. After preheating of water to the set temperature the device switches off without waiting for a signal for successive activation (temperature drop by set hysteresis). Furthermore, the boiler distinguishes with the high culture of operation, does not emit troublesome noise (<45dB) what allows installing the equipment in any place at home.

The service life of the π series induction boiler is calculated at approx. 50 years. The solutions, components used in it are purchased only from reliable suppliers. Boiler heart - heat exchanger made of stainless steel, which is installed in the transformer developed, tested, and executed on special order and only for this equipment, makes that the boiler is a device able to operate for many years.

Therefore, after registration of the device in the PEREKO portal (klient.pereko.pl), the device is provided with a 20-year warranty in compliance with the provisions given in the boiler operation and maintenance manual (DTR). Furthermore, boiler parameters for the entire period of its operation remain unchanged. Efficiency (almost 99%), capacity, operating time, or speed of water heating does not change even after 50 years.

One of the biggest advantages of the π series induction boiler is the speed of water heating in the system (or buffer tank) to the set temperature. We created a dedicated calculator for comparative and informative purposes.

The calculator indicates how fast the given model of induction boiler will heat the given amount of water by the given temperature (hysteresis). Furthermore, the second calculator available on this page, describes how much power is required to heat the given amount of water by the given temperature (hysteresis).

We invite you to tests!

π series induction boiler is a boiler of very small overall dimensions. Its compact dimensions, lack of vibrations transmission and noise-less operation, allows installing virtually anywhere. The user does not have to prepare a place for storage of fuel, build chimneys in compliance with the standards as for solid-fuel fired boilers, worry about housekeeping and dust concentration in the boiler room. The preparation of the electrical system for the boiler is very simple. Just connect it to the three-phase supply using a set of suitable residual current devices. The hydraulic system does not differ much from the systems constructed as a standard for other heating equipment, with a little exception - for π series boiler it is simpler and cheaper to install.

For an average home, it is sufficient to install a buffer tank of 700-800 liters capacity, which can be installed in every, even small boiler room. It is worth noticing that the system and operation of the induction boiler do not require the replacement of heaters (it cooperates with steel, copper or aluminum heaters) like in the case of the use of other, electric heating systems. The boiler is environmentally friendly, does not emit flue gas, waste or oxides, therefore it is not required to install any additional safety devices for the heating system.

PEREKO sp. z o.o.

ul. Eugeniusza Kwiatkowskiego 43

27-200 Starachowice

POLAND

tel. +48 41 2745353

fax +48 41 2745326

e-mail: bok@pereko.pl